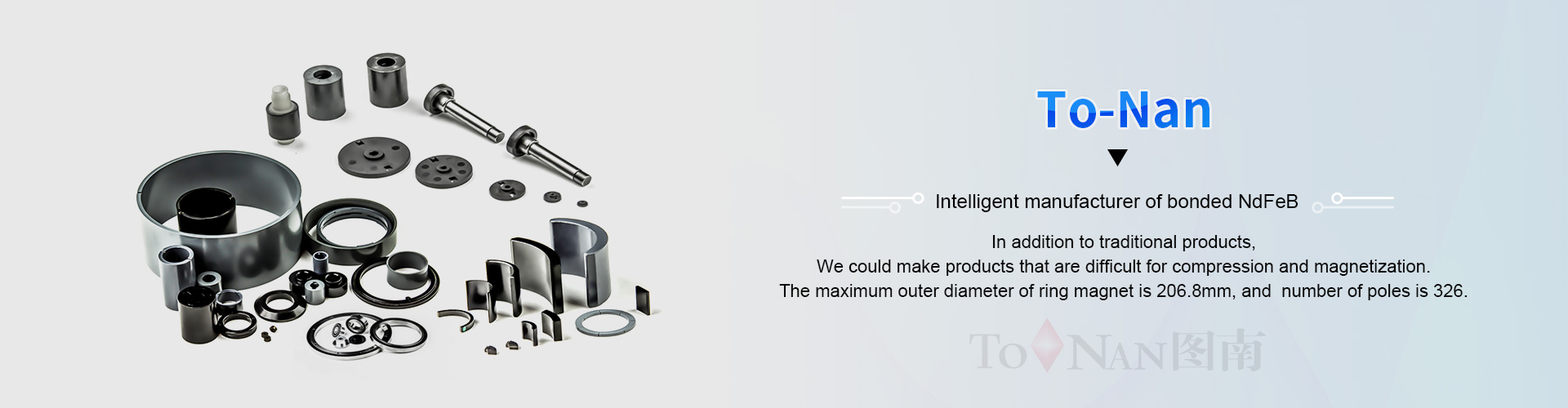

Magnet Assembly

Retail price

0.0

元

Market price

0.0

元

Number of views:

1000

Product serial number

Category

Magnet Assembly

Quantity

-

+

Stock:

Table of magnetic and physical properties

Applications

Product Process

| Product Brand | TN-1 | TN-2 | TN-3 | TN-4 | TN-5 | TN-6 | TN-7 | TN-7H | TN-8 | TN-8H | TN-9 | TN-10 | TN-10H | TN-11 | TN-12 | |

|

Residual magnetic induction |

(mT) | 290-340 | 380-420 | 380-420 | 460-500 | 480-530 | 530-580 | 610-650 | 590-630 | 630-680 | 600-660 | 650-690 | 670-710 | 640-680 | 690-730 | 700-740 |

| (KGs) | 2.9-3.4 | 3.8-4.2 | 3.8-4.2 | 4.6-5.0 | 4.8-5.3 | 5.3-5.8 | 6.1-6.5 | 5.9-6.3 | 6.3-6.8 | 6.0-6.6 | 6.5-6.9 | 6.7-7.1 | 6.4-6.8 | 6.9-7.3 | 7.0-7.4 | |

|

Coercivity |

(KA/m) | 150-200 | 180-240 | 205-255 | 230-290 | 255-320 | 295-350 | 350-415 | 390-440 | 400-440 | 380-435 | 395-440 | 410-455 | 435-480 | 420-475 | 435-495 |

| (KOe) | 1.9-2.5 | 2.3-3.0 | 2.6-3.2 | 2.9-3.6 | 3.2-4.0 | 3.7-4.4 | 4.4-5.2 | 4.9-5.5 | 5.0-5.5 | 4.8-5.4 | 5.0-5.5 | 5.2-5.7 | 5.5-6.0 | 5.3-5.9 | 5.5-6.2 | |

|

Intrinsic coercivity Force |

(KA/m) | 325-375 | 330-385 | 540-585 | 580-630 | 590-640 | 605-655 | 620-680 | 1035-1120 | 675-755 | 800-960 | 675-755 | 675-760 | 940-1025 | 675-760 | 690-815 |

| (KOe) | 4.1-4.7 | 4.2-4.8 | 6.8-7.3 | 7.3-7.9 | 7.4-8.0 | 7.6-8.2 | 7.8-8.5 | 13-14 | 8.5-9.4 | 10.0-12.0 | 8.5-9.4 | 8.5-9.5 | 11.8-12.8 | 8.5-9.5 | 8.7-10.2 | |

|

Maximum energy product |

(KJ/m3) | 14-18 | 20-24 | 25-29 | 31-35 | 39-43 | 46-50 | 60-65 | 58-63 | 66-70 | 62-66 | 69-73 | 72-76 | 70-75 | 78-82 | 82-86 |

| (MGOe) | 1.8-2.2 | 2.5-2.9 | 3.2-3.6 | 3.9-4.4 | 4.9-5.4 | 5.9-6.3 | 7.6-8.1 | 7.3-7.9 | 8.3-8.7 | 7.8-8.2 | 8.7-9.1 | 9.1-9.5 | 8.9-9.3 | 9.9-10.3 | 10.3-10.7 | |

|

Reversible permeability |

(μH/M) | 1.20 | 1.20 | 1.20 | 1.20 | 1.20 | 1.20 | 1.20 | 1.20 | 1.20 | 1.20 | 1.20 | 1.20 | 1.20 | 1.20 | 1.20 |

|

Average reversible temperature coefficient |

(%/℃) | -0.11 | -0.11 | -0.10 | -0.10 | -0.11 | -0.11 | -0.12 | -0.10 | -0.12 | -0.10 | -0.12 | -0.12 | -0.10 | -0.12 | -0.12 |

|

Saturation magnetization field |

KA/m | ≥1600 | ≥1600 | ≥1600 | ≥1600 | ≥1600 | ≥1600 | ≥1600 | ≥2000 | ≥1600 | ≥2000 | ≥1600 | ≥1600 | ≥2000 | ≥1600 | ≥1600 |

| KOe | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥20 | ≥25 | ≥20 | ≥25 | ≥20 | ≥20 | ≥25 | ≥20 | ≥20 | |

|

Maximum working temperature |

(℃) | 160 | 160 | 180 | 180 | 160 | 160 | 160 | 180 | 160 | 180 | 160 | 160 | 180 | 160 | 160 |

|

Density |

(g/cm3) | 5.1-5.3 | 5.4-5.6 | 4.8-5.0 | 5.1-5.3 | 5.4-5.6 | 5.7-5.9 | 5.9-6.1 | 5.9-6.1 | 5.9-6.1 | 5.9-6.1 | 5.9-6.1 | 5.9-6.1 | 5.9-6.1 | 5.9-6.1 | 5.9-6.1 |

|

Note: Parameters can be adjusted according to customer requirements. |

||||||||||||||||

Previous

None

Next

None

Soft Magnetic Composites

It is formed by one-time molding by using iron powder imported from

……

TEL:+86-28-87838463

TEL:+86-28-87838465

TEL:+86-28-87838465

E-mail:sales@to-nan.cn

Postcode:611731

Postcode:611731

ADD:No.599, Qingma Road, South Area, Modern Industrial Port, Pidu District, Chengdu

Copyright @ 2020 Chengdu To-Nan Electronics Co., Ltd. All rights reserved 蜀ICP备20022939号-2

- Consultation

- Consultation

- Message

- TEL +86-28-87838463

- TOP